Product / Injection Molding Machine

Injection Molding Machine

Sodick offer a wide range of injection molding machines to meet the requirements for plastic parts that satisfy consumer demands for functionality, operability, and design in these general consumer goods.

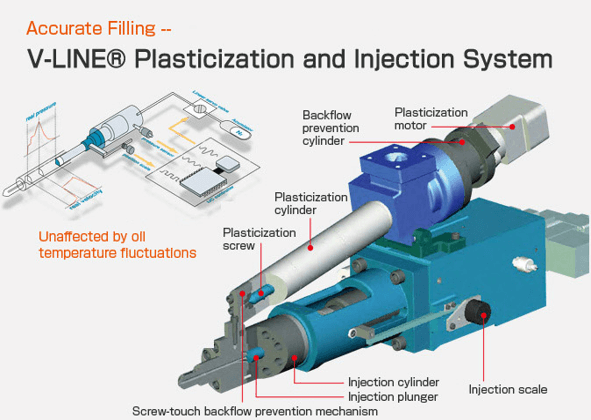

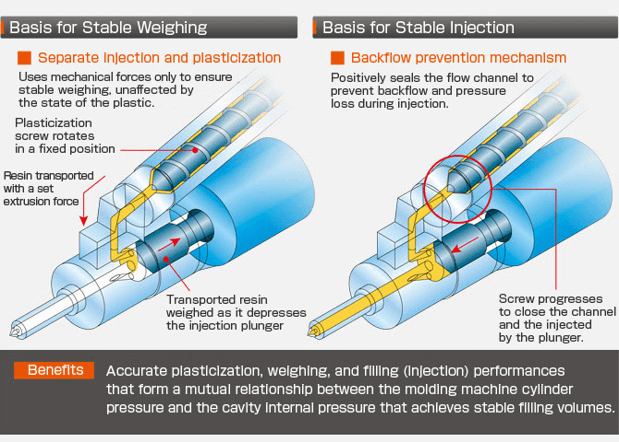

Every injection molding machine comes with a two-stage plunger injection system (V-LINE® System) which is designed on three critical principles: consistent plasticizing heat profile, constant filling volume and constant holding pressure. These principles work in perfect harmony to achieve ultra-precision injection molding.

Sodick V-LINE®System, which separates the processes of plasticization and injection. This system led to the development of the zero-backflow system. With this system, the passage is actively cut off after measuring and injection operation is then performed, so all measured resin gets injected into the mold. The birth of the V-LINE®System enabled accurate measurement of the injection amount, and control by numerical value became possible for the first time.